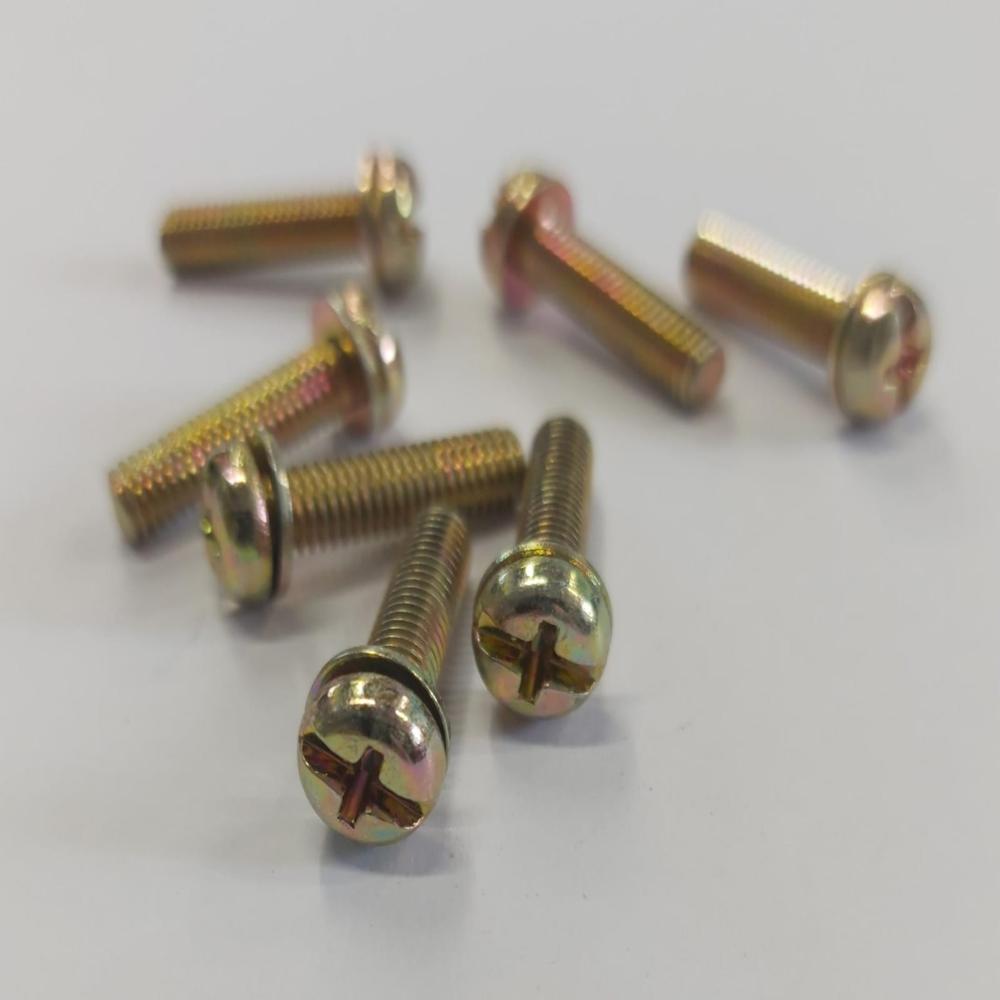

Sems Screw

Product Details:

- Surface Treatment As Per Requirement

- Corrosion Protection As Per Requirement

- Usage As Per Requiremetn

- Material Stainless Steel

- Size 10-22 Mm

- Type Stainless Screw

- Quality Level High, Premium

- Click to view more

Sems Screw Price And Quantity

- 5000 Piece

- 10.0 INR/Piece

Sems Screw Product Specifications

- 10-22 Mm

- 3-8 Millimeter (mm)

- High, Premium

- As Per Requirement

- 10-50 Grams (g)

- As Per Requirement

- 1.5-160 Millimeter (mm)

- As Per Requiremetn

- Golden

- Sems Screws

- 2-8 Millimeter (mm)

- polished

- As Per Requirement

- As Per Requirement

- Stainless Steel

- As Per Requirement

- Stainless Screw

Sems Screw Trade Information

- As Per Requirement

- Cash Against Delivery (CAD), Cash on Delivery (COD), Cash Advance (CA), Cash in Advance (CID), Cheque, Days after Acceptance (DA), Delivery Point (DP), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Letter of Credit (L/C)

- 1500000 Piece Per Month

- 1 Week

- Yes

- Contact us for information regarding our sample policy

- Asia, Australia, Central America, North America, Eastern Europe, Western Europe, Middle East

- All India

Product Description

Our firm specializes in offering an excellent range of Industrial Sems Screw. Tested on several parameters set by the industry, this product is extensively demanded all across the globe. Offered range of screw is widely demanded in various industries for fastening many tools and appliances. This is highly appreciated among our client for its outstanding service life, easy installation, tough construction, robust design, corrosion resistance and requires low maintenance cost. Clients can avail the provided Industrial Sems Screw from us at nominal prices.

Washers are often used in combination with screws to improve the structural integrity of an assembly. Typically, they are separate components. However pre-assembled screws and washers " the SEMS screw, have simplified and improved efficiencies in many manufacturing processes.

A SEMS Screw is a generic term used to describe a screw pre-assembled with a free-spinning lock washer. It is a permanent assembly with the washer held in place by the major diameter of the screw thread being larger than the hole of the washer. The SEMS screw is simple, easy to use and available in many different styles making it well suited for many applications.

It is also known as Screw with Washer assemblies, Terminal Screws, Self-Lifting Washer Screw, Screw with Integrated Washers, Captive Screw, Self-Lifting Washer Assembly Screws, Sems Fasteners, Sems Machine Screw, Sems Bolt etc.

ADVANTAGES OF THE SEMS SCREW:

- Low cost and widely available

- Increases productivity by eliminating hand assembly of individual components

- Permanent assembly assures that the washer is not dropped, lost or forgotten

- Ease of use with hand drivers and in automated production programs

- Available in most screw and washer combinations

MATERIAL:

- Mild Steel (MS)

- Brass

- Stainless Steel

- Copper

- Silicon Bronze

- Phosphate Bronze

THREADS:

- 2 MM to 8mm

- 1/8 to 5/16

- 8 BA to 2 BA

LENGTH:

- 4 MM to 150 MM

- 3/16 to 6

STANDARDS:

ISO, IS, DIN, BS, JIS

FINISHING:

- Nickel Plating

- Trivalent Passivation

- Chrome Plating

- Tin Plating

- Copper Plating

- Blue Yellow White Black Zinc Plating

- Silver Plating

- Gold Plating

- Brass Plating

- Any other coating as per customer requirements

Any types of Screw can be developed as per customers requirement & specifications.

Sturdy Construction

Manufactured from premium stainless steel, our Sems Screw is engineered for robust performance in demanding environments. The polished golden finish adds aesthetic appeal while also enhancing surface protection against wear and corrosion.

Versatile Sizing

With a comprehensive range of sizes and lengths, these screws offer flexibility for different installation requirements, from intricate assemblies to large-scale construction. This versatility ensures compatibility across various applications and industries.

Indian Manufacturing Excellence

As a leading exporter, manufacturer, and supplier in India, we commit to precision engineering and stringent quality control. Our focus is on delivering products that meet international standards, ensuring satisfaction for both domestic and global clients.

FAQs of Sems Screw:

Q: How can Sems Screws be used in industrial applications?

A: Sems Screws are suitable for fastening machinery parts, assembling electrical components, and securing panels in various industrial sectors. Their robust stainless steel construction ensures long-term reliability in high-stress environments.Q: What advantages does the polished golden finish offer?

A: The polished golden finish not only provides a visually appealing look but also adds an extra layer of corrosion resistance, making the screw suitable for both indoor and outdoor applications.Q: When should I choose a stainless steel Sems Screw over other types?

A: Opt for stainless steel Sems Screws when you need superior durability, resistance to oxidation, and longevity, especially in environments prone to moisture or chemicals.Q: Where are Sems Screws manufactured and supplied from?

A: Our Sems Screws are manufactured and exported from India, adhering to rigorous quality standards to serve a global client base.Q: What is the process of manufacturing Sems Screws?

A: These screws are produced using advanced machining and finishing processes, including cold forging and precise polishing, to ensure optimal strength and a smooth, gleaming surface.Q: How do I select the correct size and length for my project?

A: Determine the thickness and material of your components, then select from our size range (10-22 mm) and available lengths (1.5-160 mm) to ensure a proper fit and reliable fastening.Q: What are the key benefits of using these Sems Screws?

A: They offer excellent mechanical strength, corrosion resistance, versatile sizing options, and an elegant finish, making them ideal for both functional and decorative purposes in various applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese